Use Caution when Cleaning and Disinfecting

Cleaning and disinfecting are essential for keeping bacteria and viruses out of schools, but improper chemical use can cause burns, eye injuries, or respiratory issues. Follow these best practices to protect custodians, maintenance staff, and others who use chemical products.

Choose Safe Products

The Environmental Protection Agency (EPA) Safer Choice program identifies cleaning products that are safer for people and the environment. You can also explore spray-and-wipe disinfectants as a cost-effective alternative.

Compliance Tip

Do not allow employees to bring personal chemicals to work All chemicals used in the district must have a Safety Data Sheet and label (see next section). Unauthorized chemicals violate the Texas Hazard Communication Act.

Rely on Labels and SDSs

The Texas Hazard Communication Act requires employers to maintain labels and Safety Data Sheets (SDSs) for all hazardous chemicals. SDSs outline hazards, safe handling, required protective equipment, and storage guidelines. Review the SDS in advance to ensure the product is appropriate.

Train the Team

Employees must be trained to safely handle the chemicals and equipment they use. Those who work with chemicals must complete annual Hazardous Communication training. Employees at risk of occupational exposure to blood or other potentially infectious materials must also take Bloodborne Pathogen Training.

Store Chemicals Securely

The Centers for Disease Control and Prevention advises schools to store chemicals securely, out of students’ reach and sight, with lids tightly closed. Storage must follow label instructions. Some chemicals, including those used in labs and shops, require additional storage procedures.

Use PPE Properly

Personal protective equipment (PPE) puts a barrier between hazards and employees. Because PPE could be damaged or improperly fit, you should always consider it the last line of defense. Start by removing hazards or reducing employees’ exposure when possible. For example, you might be able to substitute a hazardous cleaning product for a less-hazardous alternative.

PPE requirements vary by product, but these forms of PPE typically apply when working with hazardous chemicals.

Gloves, gowns. Use gloves and gowns to prevent direct skin exposure. Clothing should cover all skin except the hands and face. Remind employees remove gloves and gowns carefully and wash their hands immediately. Employees should talk to their supervisor to ensure disposable PPE is properly discarded after each use.

Eye, face protection. Goggles or safety glasses, face shields, and face masks that cover the nose and mouth protect employees and guard against chemical splashes.

Respirators. The market offers a variety of respirators that reduce chemical fume exposure. Apply these general principles when employees use respirators:

- Remember that single-use “dust masks” are not respirators, and they do not protect against hazardous chemicals.

- Consult chemical labels and Safety Data Sheets for guidance on which respirators to use, and train employees to wear a respirator properly (English, Spanish).

- Before employees wear respirators, they must have a medical evaluation and fit test. They must also conduct a respirator seal check before each use.

Avoid Combining Chemicals

Do not mix cleaning or disinfecting products without reading their labels and SDSs. Incompatible chemicals—like bleach and ammonia—can create toxic gases that cause severe lung damage or death. Also, avoid storing chemicals in containers that do not have the correct label or instructions.

Don’t Overuse

Overusing cleaning or disinfecting products can pose health risks. Always follow the manufacturer’s instructions and ensure towels are free of oil, dirt, or chemical residue before use.

Ventilate the Area

Open doors and windows to ventilate facilities and buses where chemicals were recently used, but always prioritize security. During extended cleaning and disinfecting, employees should step outside periodically for fresh air.

Call on the Fund

Maintaining a clean and healthy school environment is essential—but it must be done safely. By choosing safer products, following label and SDS guidance, using proper protective equipment, and training employees, schools can protect staff and students. If you have questions, regionally based risk solutions consultant is here to support you.

Editor's note: This article was originally published in November 2020. It has been updated for accuracy and comprehensiveness.

Nicole Callahan

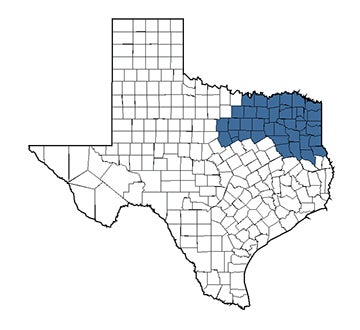

Nicole Callahan is located in Rowlett and is responsible for providing risk solutions services to Workers’ Compensation, Auto, Property, and Liability members in ESC Regions 8, 10, and 11 and most of Region 7.

Callahan joined TASB Risk Management Services as a risk solutions consultant in 2018. She began her environmental career in 2002. Callahan’s field service experience in the public and private sectors ranges from plant decommissioning to high-hazard emergency response.

You May Also Like…

View All Related Insights

How To Manage and Mitigate Your Burn Risks

From bustling kitchens to science labs to maintenance and transportation shops, there are plenty of opportunities for burns to occur at your school or community college.

The Importance of a Thorough Accident Investigation

Conduct accident investigations to uncover the root causes of workplace injuries, correct them, and reduce the risk of similar injuries.

Are You Managing Electronic Waste Safely and Compliantly?

Before you dispose of electronic devices or transfer them to students, make sure they're wiped clean of sensitive data.

Complete These District Audit Report To-Do’s Before Summer Break

Districts should conduct climate surveys and intruder assessments while stakeholders are accessible and staff, students, and visitors are coming and going.