Upgrade Rooftop Resilience with Hail Guards

Hail can damage most exposed surfaces, but the majority of damage is to roofs, followed by damage to heating, ventilating, and air conditioning (HVAC) equipment. How can Fund members minimize weather damage to rooftop features, control operational interruptions, and avoid unnecessary repair costs? Preventive design and routine maintenance are two strategies that can protect your costliest facility investments.

Hail Guards and Shields

Whether on the rooftop or on the ground, HVAC equipment is vulnerable to damage during severe weather, especially when left unprotected. HVAC equipment varies in size and type, but the common features are at risk: condenser fins, coils, and fan blades.

While minor damage can be repaired during routine maintenance, stronger hailstones easily dent, bend, and break these softer metal components, reducing their lifespan by forcing systems to work harder. Post-storm investigations have shown that HVAC fins sometimes suffer dents measuring twice the size of the hailstones that caused them.

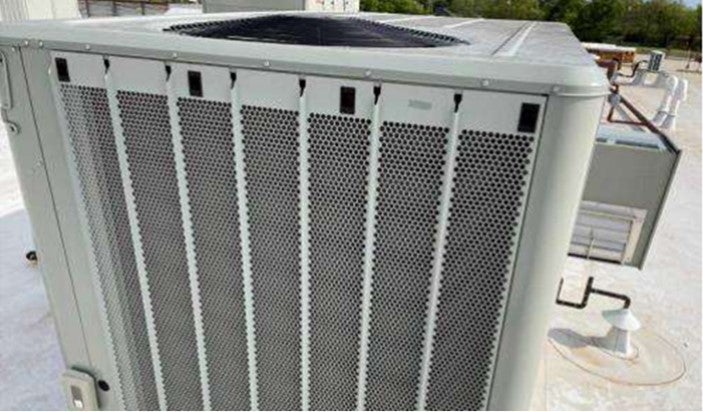

Steel mesh protected the fins and coils on this HVAC unit when a storm passed through North Texas.

Hail damage can often be prevented by installing hail guards or shields over condenser fins. These are “specially designed protection systems that cover outdoor equipment components while allowing for adequate airflow.” (Insurance Institute for Business & Home Safety)

FM Approvals, an international third-party testing and certification agency, recommends “installing hail guards or steel wire mesh over all cooling fins” on HVAC equipment. This includes a “minimum No. 11 gauge diameter steel wire mesh with a maximum mesh opening size of 0.5 in. - 1.0 in. supported on a steel framework.”

These improvements help protect against hail and wind, and this information can be referenced in FM Approvals Property Loss Prevention Data Sheet 1-34: Hail Damage. Hail guards are available as an option from HVAC manufacturers but can also be obtained from other suppliers.

All rooftop HVAC equipment, including retrofitted hail guards, should be properly fastened and secured to prevent movement during high winds. Hail guards are specifically engineered for proper air flow and should not be substituted with screen or mesh material not intended for this use. Depending on the manufacturer, hail guards can be UV protected and resistant to rot, weather, abrasion, and corrosion. This equipment should only be installed by qualified personnel.

Additional Considerations

Why are some HVAC units installed with hail guards and some without? Specifications play an important role with any construction or renovation project, whether you’re opening a formal bid or using your local supplier. These criteria act as the targets and parameters the contractor must follow, clearly stating the standards that must be met and ensuring the final product is relevant to the initial purpose.

Meanwhile, these unprotected HVAC units suffered significant hail damage. The member had to replace four rooftop units on a single campus at a cost of more than $800,000.

If minimum hail protection is not specified, new equipment is installed without it, significantly reducing life expectancy and increasing the chance of preventable business interruption.

Understanding the various roles and respective responsibilities as well as holding individuals accountable to meeting adequate standards through clear specifications and oversight are vital to ensuring the finished project is a sound investment.

During major replacements or new construction projects, it’s also common for sticker-shock to set in. With an eye toward reducing immediate project costs, districts sometimes make short-sighted choices to disregard weather resilience upgrades such as hail guards on HVAC equipment and reinforced cover boards in roofing assemblies.

Remember that facilities operating with poor weather resilience standards leave building owners exposed to significant financial risk.

Takeaways

Routine inspection and maintenance are necessary to extend the life expectancy of high-value systems and equipment. These few but important steps can be added to the checklist for staff conducting monthly preventive maintenance on HVAC units.

- Check with your HVAC vendor before retrofitting HVAC units with a different brand of hail guards. You might void your warranty.

- Retrofitted hail guards should be monitored for reduction in airflow to minimize impact to the compressors.

- Hail guards should be kept free of debris and other obstructions.

- Fasteners and screws should be checked to ensure they are secure.

- Sometimes, guards or shields must be removed for equipment servicing and maintenance. By adding protection, districts will likely reduce the need to clean the condenser coils or comb the fins.

Joanie Arrott

Joanie Arrott joined TASB Risk Management Services in 2009 after serving five years with TASB Facility Services. She leads a team of regionally based consultants who specialize in controlling workplace accidents, property damage, vehicle collisions, and other risks in Texas public schools.

You May Also Like…

View All Related Insights

Protect Your Fleet With a Preventative Maintenance Plan

If you want to protect your vehicles and their passengers, you need an effective preventative maintenance plan.

8 Steps to a Preventative Maintenance Program

Preventative maintenance can save money for schools and minimize operational disruptions by extending the lifecycles of roofs, boilers, and other property.

TASB Risk Management Fund Prevails in Property Claim Lawsuit

The TASB Risk Management Fund won a unanimous jury verdict in Coleman County against a property claim lawsuit brought by a West Central Texas school district.

Extreme Weather, Inflation Create Challenging Property Market

The increased frequency of natural disasters is creating a hard property market, making it challenging when going out to bid or renew.