Your Step-by-Step Guide to Chemical Inventory Cleanout

Schools house hundreds of chemicals for experiments, maintenance, pest control, and disinfection. If mislabeled, expired, or improperly stored, chemicals can pose serious risks and lead to unexpected costs.

Pressurized gases like helium should never be used as door stops, and oil-based paints stored on wooden shelves create a fire risk.

You should clean out your expired or unused chemicals at least once a year. Summer is ideal because facilities are less occupied. Follow these steps to do the job safely and cost-effectively.

Step 1. Take Stock

Start by taking a full inventory, including maintenance areas, custodial closets, science labs, and auto shops. Record this data at minimum:

- Chemical name

- Container size (not the remaining amount)

- Container material (glass, plastic)

- Physical state (solid, liquid, gas)

Pro tip: Share your inventory with local fire, police, and EMS as part of your emergency operations plan. First responders might need the information if a chemical-related explosion, fire, spill, or other emergency happens at a school facility.

Step 2. Clean Storage Areas

Only trained staff familiar with chemical hazards and personal protective equipment should clean storage areas—chemistry teachers are often well-suited. Remove spilled or leaked residue first.

- Use compatible, absorbent material for liquids.

- Sweep solids into appropriate containers with a broom and dustpan.

- Clean or discard equipment after use to prevent cross-contamination.

Note: Always consult Safety Data Sheets before using cleaning products to avoid dangerous reactions.

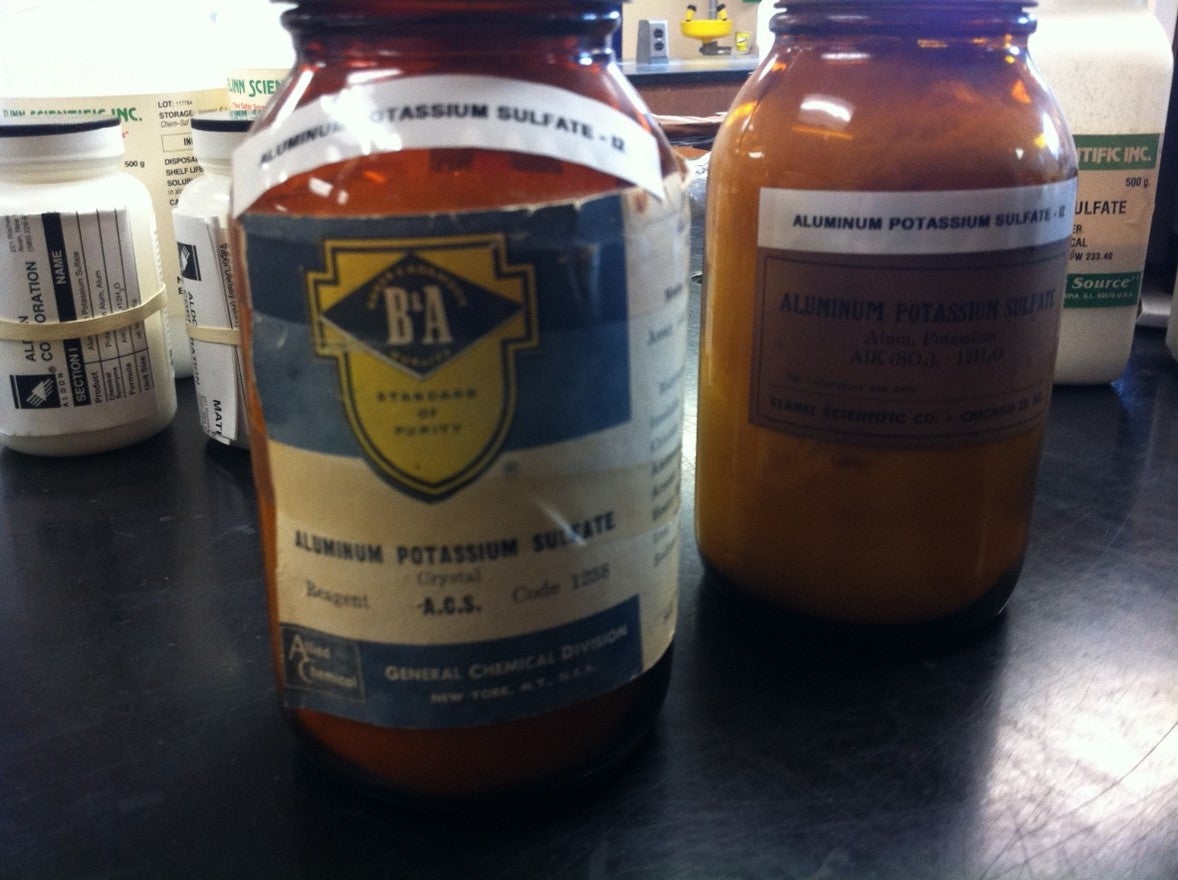

This chemical, found in a school science lab, likely dates to America's space race.

Step 3. Decide What to Keep

You do not have to keep chemicals just because they still have shelf life or they are in good condition. Use your organization’s approved product list to guide decisions. If a chemical isn’t needed, consider donating it—following proper transport procedures.

Storage Tips:

- Keep no more than a three-year supply unless justified.

- Consult Section 7 of the safety data sheet (SDS) for storage and compatibility guidance.

- Use original or approved secondary containers. Avoid Tupperware, jelly jars, water bottles, and anything used to store food or beverages.

- Label containers properly.

- Stick to two rows of chemicals per shelf if possible.

- Store chemicals with compatible materials on shelves or in specified cabinets, such as Flammable or Corrosive.

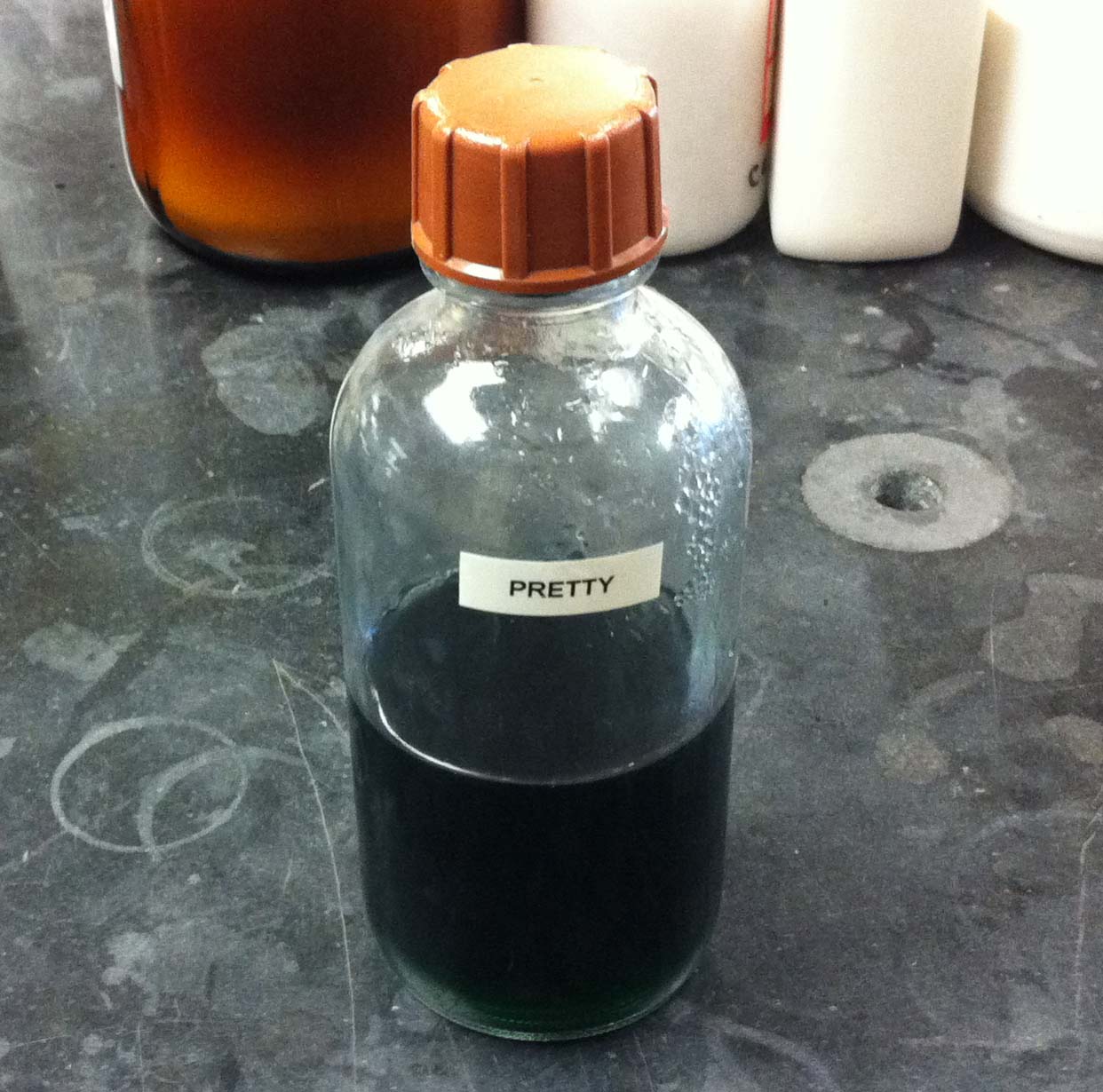

Mislabeled chemicals are not only dangerous. They violate the Texas Hazard Communication Act.

Step 4. Update SDSs

The Texas Hazard Communication Act requires public employers to keep an SDS for every chemical on-site, regardless of quantity. SDSs can be hard copy or electronic, but they must be readily available to employees and emergency responders. Replace outdated or missing SDSs or material safety data sheets, which are obsolete, by contacting the manufacturer or distributor.

Training Reminder

Summer is also a good time to ensure employees have been trained to interpret SDSs and chemical container labels. Employers are required to maintain training records for at least five years. Keep the attendance roster and document:

- Training date

- Topics covered

- Instructor names

Step 5. Prepare for Disposal

Identify and set aside chemicals that are:

- Expired

- Unlabeled

- Leaking or damaged

- Missing proper lids

Important: Never pour chemicals down the drain or throw them in the trash. Hire a certified lab packing company for disposal.

Ensure containers are safely stored while awaiting pickup:

- Use secondary containment (e.g., spill platforms)

- Label the area “Hazardous Waste”

- Restrict access to authorized personnel

School staff should not store hazardous chemicals near areas where food or beverages are consumed or stored.

Beware of Buying in Bulk

Bulk purchases may seem cost-effective but can lead to waste and high disposal costs. Consider hydrochloric acid (HCL), a chemical commonly used in science experiments:

- 1 oz of HCl = $20

- 5 oz = $30 ($6/oz)

- If you only use 0.5 oz/year and it expires in 2 years, you’ll dispose of 3 oz—potentially costing $200 in disposal fees.

Ready to Dive Deeper?

If you need help disposing of chemicals, your risk solutions consultant is here for you. Fund members with Workers’ Compensation, Property, or Liability coverage can also watch this on-demand webinar: Safety and Savings – 2 Reasons to Manage Chemical Inventory.

Editor's note: This article was originally published in June 2020. It has since been updated for accuracy and comprehensiveness.

Nicole Callahan

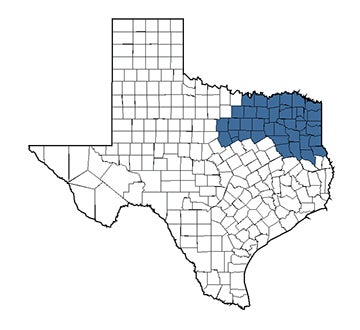

Nicole Callahan is located in Rowlett and is responsible for providing risk solutions services to Workers’ Compensation, Auto, Property, and Liability members in ESC Regions 8, 10, and 11 and most of Region 7.

Callahan joined TASB Risk Management Services as a risk solutions consultant in 2018. She began her environmental career in 2002. Callahan’s field service experience in the public and private sectors ranges from plant decommissioning to high-hazard emergency response.

You May Also Like…

View All Related Insights

How To Manage and Mitigate Your Burn Risks

From bustling kitchens to science labs to maintenance and transportation shops, there are plenty of opportunities for burns to occur at your school or community college.

The Importance of a Thorough Accident Investigation

Conduct accident investigations to uncover the root causes of workplace injuries, correct them, and reduce the risk of similar injuries.

Are You Managing Electronic Waste Safely and Compliantly?

Before you dispose of electronic devices or transfer them to students, make sure they're wiped clean of sensitive data.

Complete These District Audit Report To-Do’s Before Summer Break

Districts should conduct climate surveys and intruder assessments while stakeholders are accessible and staff, students, and visitors are coming and going.